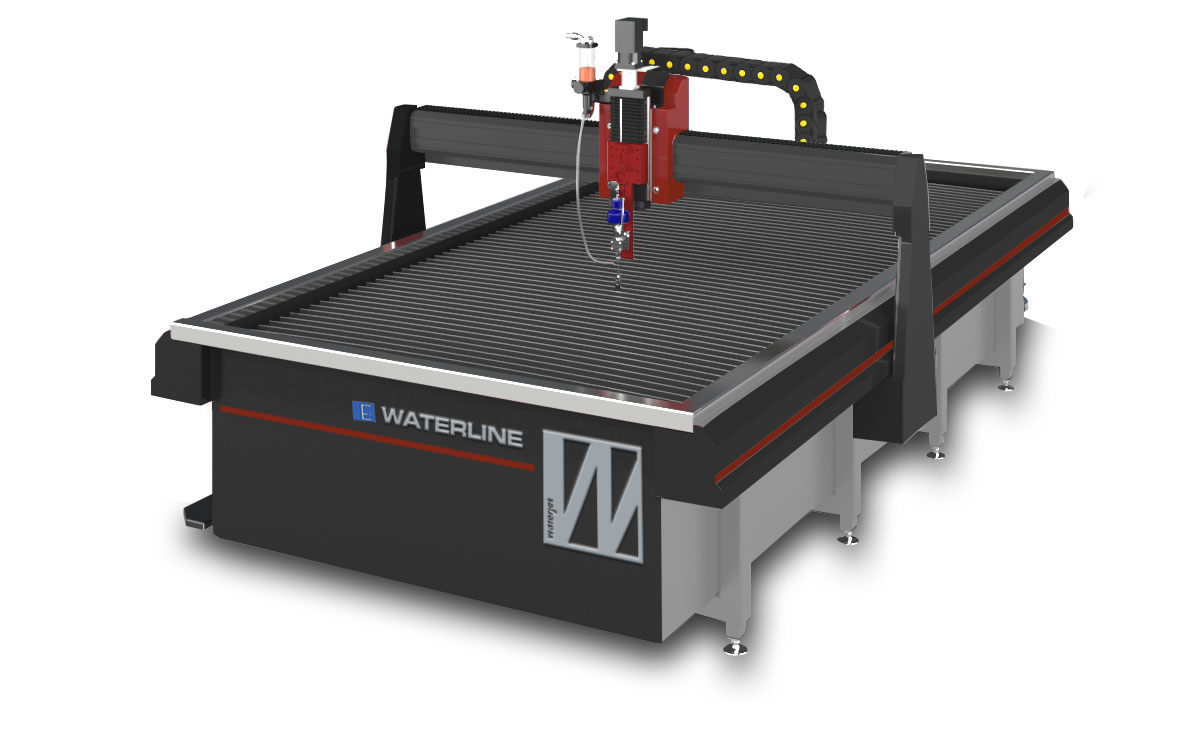

Waterjet entry level machine

WATERJET WATERLINE - WL 510

| Net Cutting Area | X = 3.400 mm (11') Y = 1.650 mm (5' 1/2) Z = 200 mm (8") |

| Inner Table Working Area | 3.800 mm x 1.800 mm (12' x 6') |

| Overall Dimensions | 4.000 mm x 2.300 mm x h 1.800 mm (13' x 8' h x 6') |

| Rapid Speed | 0 - 20 mt / min (0-67' / min) |

| Weight | 2.000 Kg (5.000 lb) |

| Positioning Accuracy | ± 0,1 mm (± 0,004") |

| Repeatability | ± 0,05 mm (± 0,002") |

| Ballbar Ø 300 mm (12”) | ± 0,1 mm (± 0,004") |

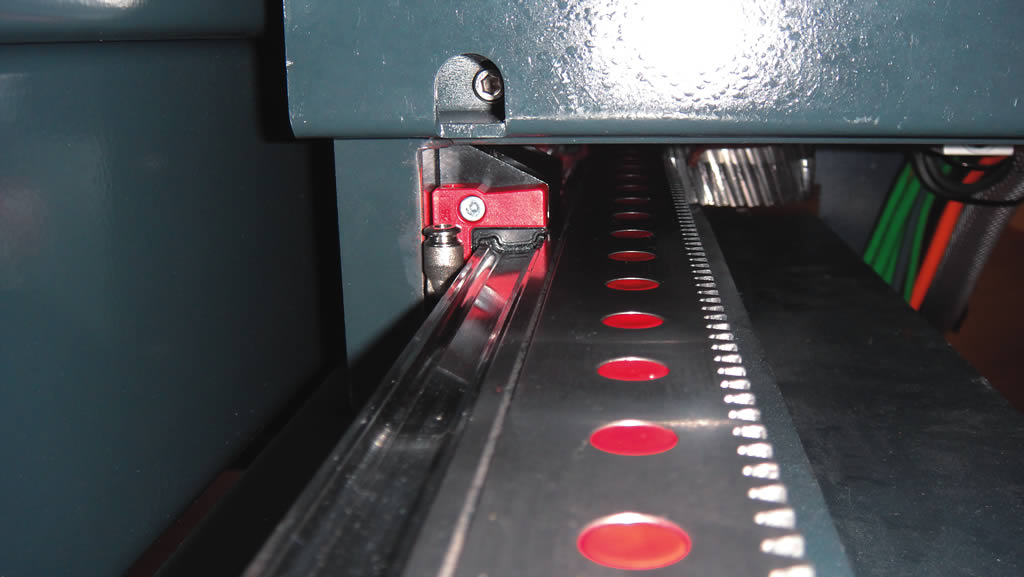

EDGE 5 axis ±55° with I.T.C. (Intelligent Tapering Control) technology and exclusive Touch Wave™ sensor for accurate continuous position calibration.

STANDARD AVAILABLE MODELS

| WL 44 | 1.250 x 1.250 mm (4' x 4') |

| WL 512 | 3.400 x 1.650 mm (11' x 5' /2) |

| WL 612 | 4.000 x 2000 mm (13' x 5' 1/2) |

Italiano

Italiano Deutsch

Deutsch Français

Français