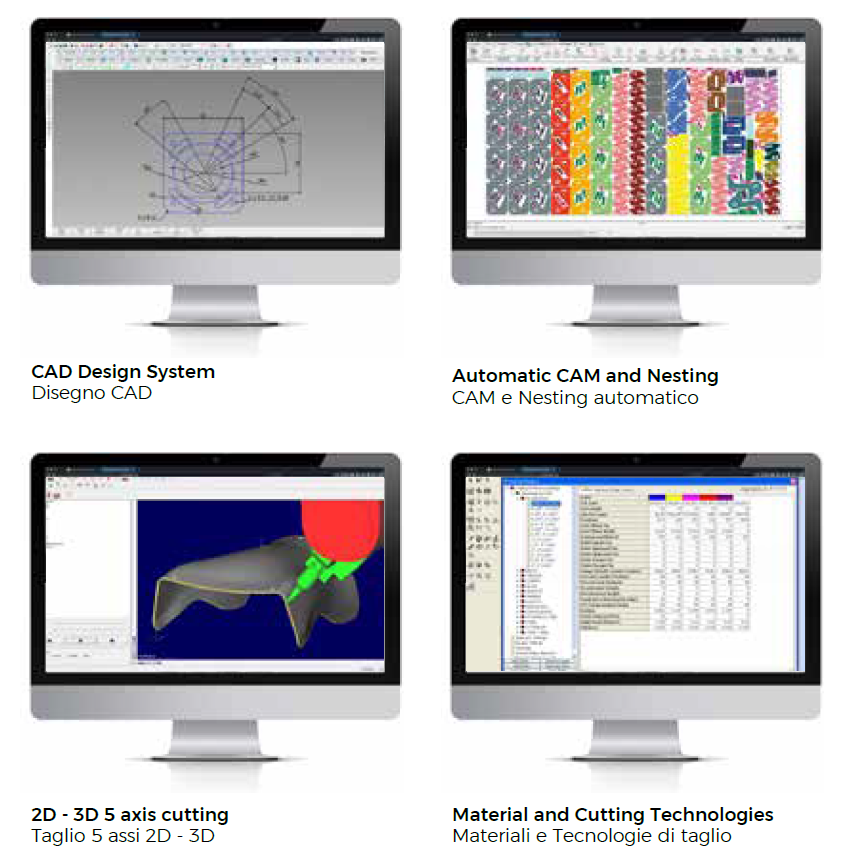

CNC & HMI & Software CAD/CAM

SOFTWARE CAD-CAM

WATERJET HMI

ELECTRIC PUMP HMI

HYDROFINISH HMI

PRODUCTION LINE HMI

WaterCad-Cam is a CAD/CAM solution designed to easily automate the programming of Waterjet machines.

Within the same program environment, you can design or import a part by DXF, DWG consult the plate warehouse, perform manual or automatic nesting, execute manual or automatic cutting sequences, generate the NC program and calculate time and costs.

In the technological tables MATERIAL, THICKNESS and FINISHING for the required task can be selected; an ISO program (NC Code) is automatically generated, ready for uploading to the CNC by ETHERNET or USB.

The software also allows for an estimations related to the programmed job prior to the actual cutting being

run, showing COSTS, TIMING and CUTTING LENGTHS.

WATERJET HMI

- The Graphic-Window shows the shape of the work piece and the cutting path, it can be used to define the start point for the restart function.

- The Display-Bar shows Position, Time, Offset, Feedrates and Override data.

- Operational Functions for the different Modes (Jog, Manual, Automatic).

- Main menu switches for the different Modes.

- Main Switch Board.

- Emergency switch.

- Override.

- Remote diagnostic.

ELECTRIC PUMP HMI

- Working Pressure.

- Power Consumption.

- Temperature Check Valve Right.

- Temperature Check Valve Left.

- Cooling Temperature Right.

- Cooling Temperature Left.

- Time Cycle.

HYDROFINISH HMI

.jpg)

- Material List Display.

- Menu Bar.

- Function Buttons.

- Power on Auxiliary and Axis.

- Emergency Switch.

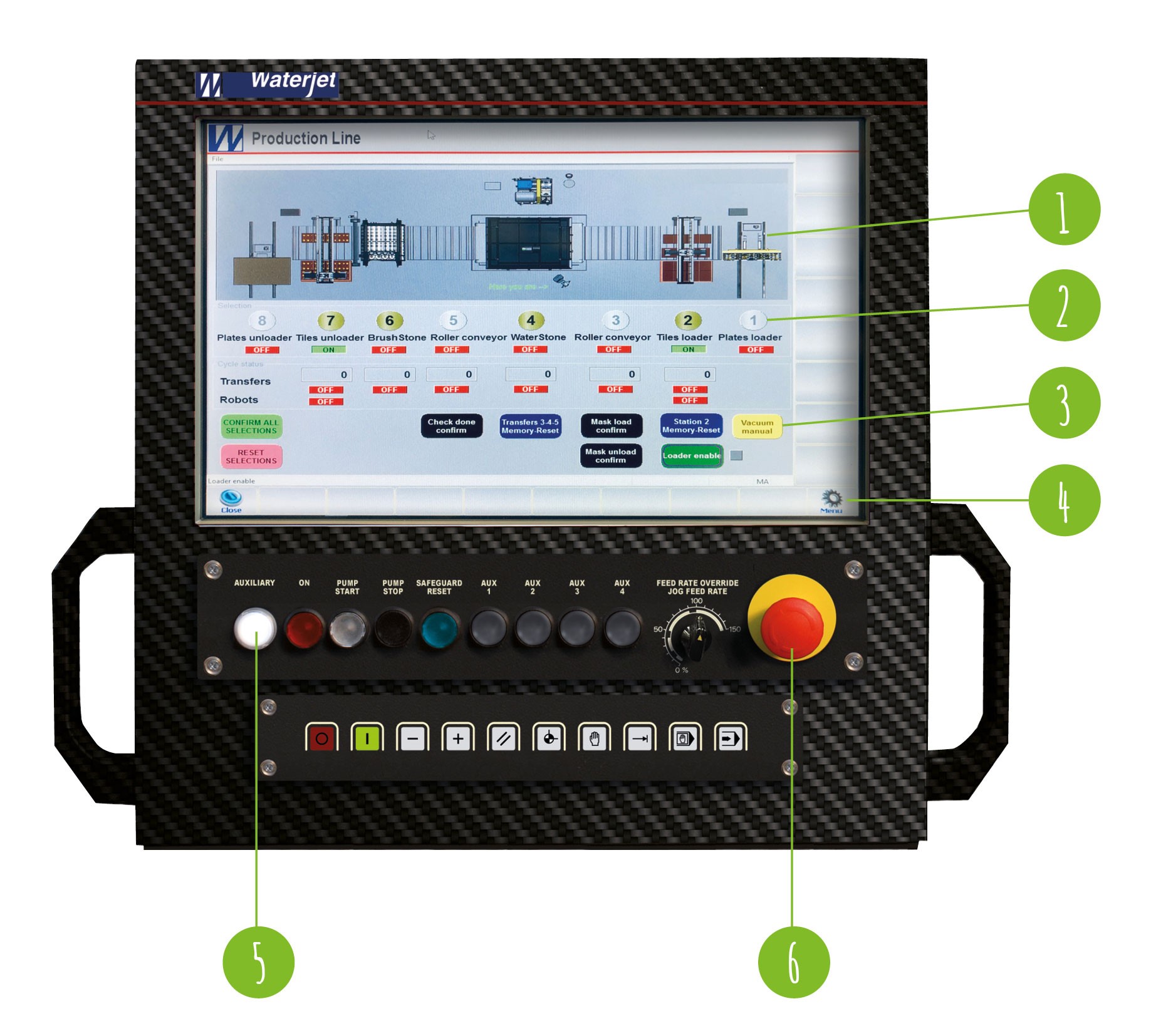

PRODUCTION LINE HMI

- System lay out.

- Equipment and working process selection.

- Customized parameters selection.

- General menu for material selection.

- Main switch board.

- Emergency switch.

Italiano

Italiano Deutsch

Deutsch Français

Français