3 INTEGRATED TECHNOLOGIES

TO REDUCE PROCESSING TIME AND COSTS

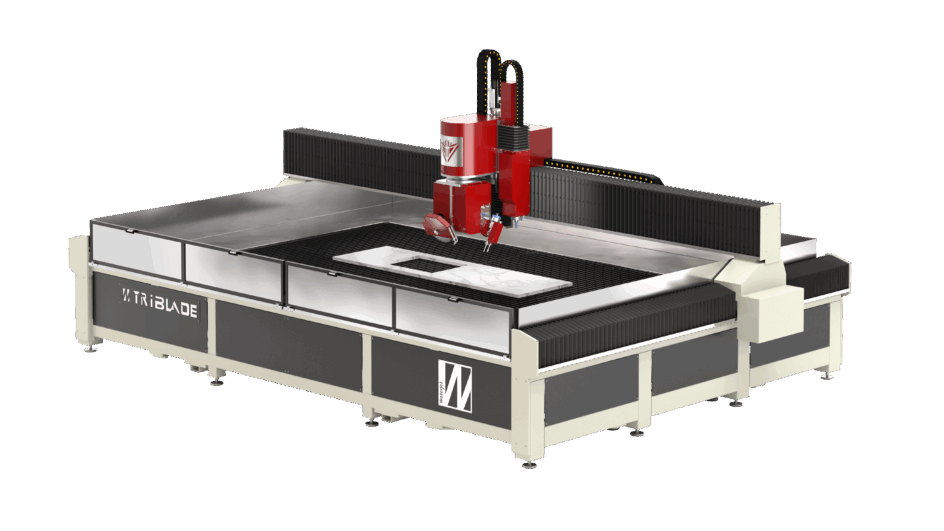

TRIBLADE™ is the waterjet machine that integrates three technologies in a single solution: 5-axis waterjet cutting, diamond blade and 3-axis milling.

Designed for machining kitchen countertops, bathrooms and wall tiles with maximum precision and sustainability.

WHAT MAKES TRIBLADE UNIQUE

UNIQUE PROCESS, ZERO REPOSITIONING

Reduces time, space, and handling.

MAXIMUM PRODUCTION FLEXIBILITY

Seamless and automatic transition from one

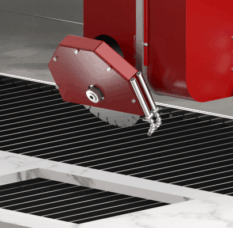

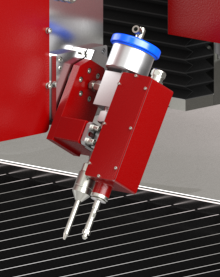

technology to another (Disc, Waterjet, Milling).

COMPLEX CUTS, HIGH PRECISION

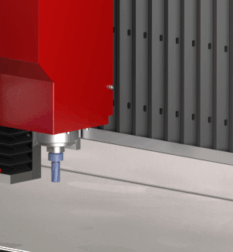

5-axis waterjet for complex geometries and impeccable finishes.

OPTIMIZED CYCLE TIMES

Fast disc cutting on straight lines, working in perfect synergy with the waterjet.

OPERATIONAL SAVINGS AND SUSTAINABILITY

High-efficiency Synchro / Edrive / Servo* / Hyper* pump for low energy impact.

*(BFT Technology)

Download brochure

Per poter scaricare la brochure occorre inserire i dati richiesti nel seguente modulo. Riceverai un'email contenente il link al PDF.

The Details of TRIBLADE

Waterjet machines guarantee in italy precise cold cutting on a variety of materials, including metal, glass, stone, composites and insulating materials.

-

Exceptional versatility and cutting precision

Minimum waste of processed material and significant reduction in production time and costs thus eliminating finishing steps after the cutting stage.

-

User-friendly

The programming operations are very simple. You can select and start the custom work program for any material or thickness with just a few clicks.

-

Versatility

The machines that we produce allow any shape, size or material to be cut, up to a maximum thickness of 300 mm. Since this is a cold cutting process, no mechanical or thermal deformations occur in the processed material, which is very important in the case of state-of-the-art materials.

-

Eco-sustainability

We have adopted efficient production processes and responsible resource management to cut down on waste. We invest in environmentally friendly technology and involve our employees in sustainable initiatives that are the key to building an environmentally advanced business model.

Features

Discover about all the technical features of our most innovative solution on the market.

| TRIBLADE TB 612 | |||

|---|---|---|---|

| Pump Power: | 26 ÷ 37 kW | ||

| Net Working Area: | X = 4.000 mm (13') Y = 2.000 mm (6' 1/2) Z = 300 mm (12") |

||

| Internal Tank Dimensions: | 4.250 mm x 2.750 mm (14' x 9') |

||

| Machine Dimensions: | 6.700mm x 4.600 mm x h 2.500 mm (22' x 15' x h 8') |

||

| Total Machine Weight: | 7.500 kg 16.700 lb |

||

| Diamond Disc Motor Power: | 5 kW | Spindle Power: | 3.7 kW |

| Max Diamond Disc Rotation Speed: | 3000 rpm | Max Spindle Speed: | 14000 rpm |

| Diamond Disc Diameter | 300 ÷ 400 mm 12” ÷16” | Positioning Accuracy / Length: | ± 0,075 mm± 0,003” |

| Cutting Depth | 30 mm 1.18” | Repeatability: | ± 0,05 mm± 0,002” |

| Minimum and Maximum Tool Diameter | 12 ÷ 20 mm1/2” ÷ 3/4” | Circularity Accuracy Ø 300 mm / 12”: | ± 0,075 mm± 0,003” |

| Rotation C axis | ± 380° | IInclination A axis: | ± 55° |

For any information, please contact us.

If you didn't find what you were looking for while browsing, or if you have any requests to submit to us, do not hesitate to contact us by filling in the form. We will answer you soon.

* Required fields

You might also be interested in this

Cantilever

Entry level waterjet machine, 3 axis with integrated tank. Optimal for simple processing.

Cantilever

Flexible waterjet system for the number of accessories that could be combined. 3-axis system with separate tank. Suitable for customizations.