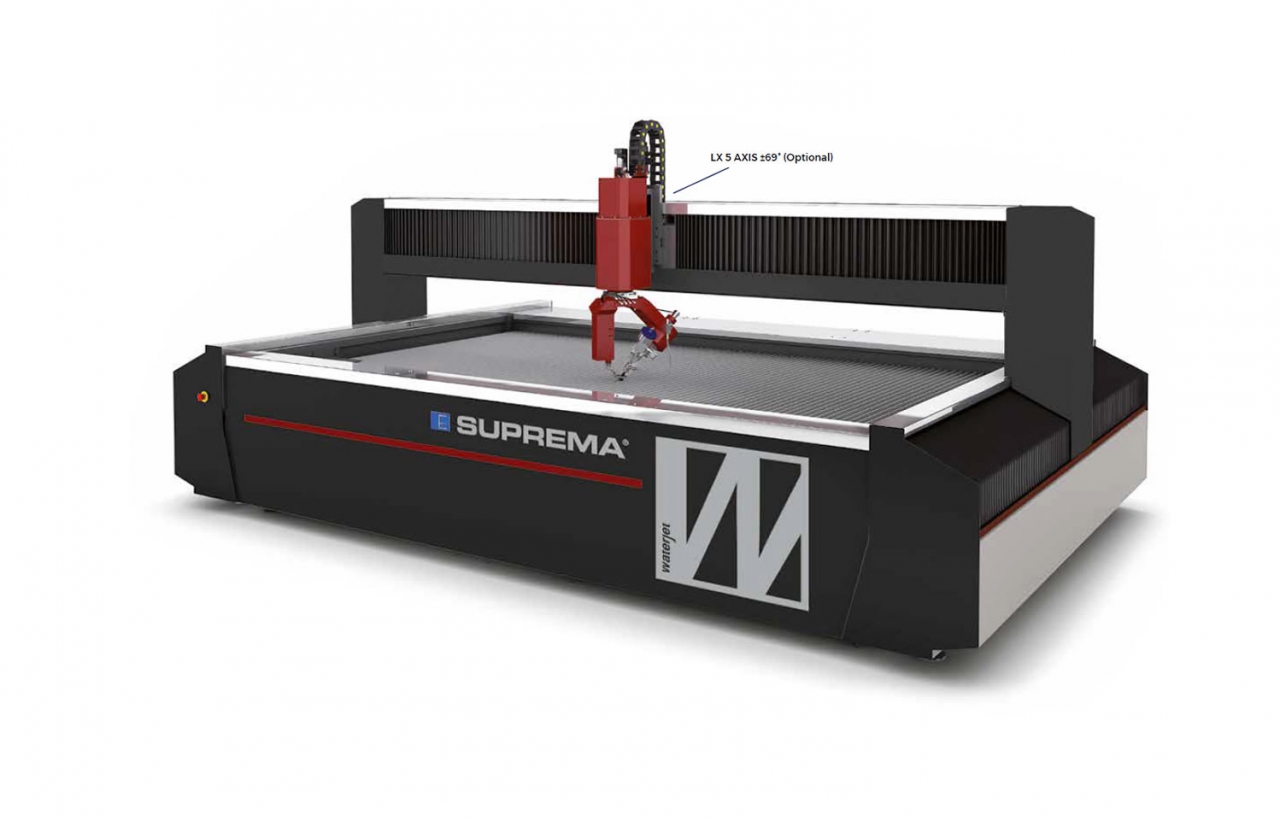

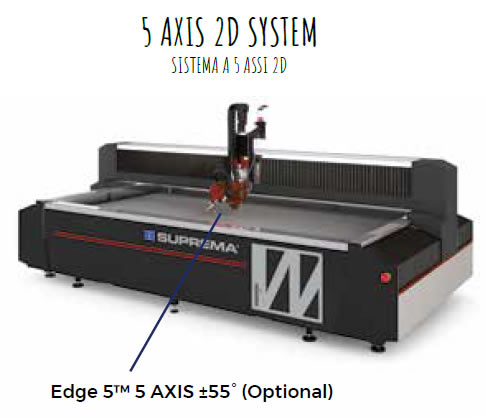

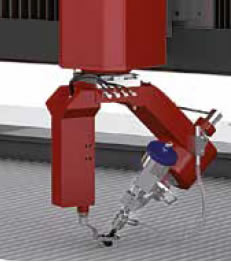

5 AXIS 3D WATERJET MACHINE BY TOUCH WAVE™ SENSOR

The cutting system has the following characteristics:

► separate stainless steel tank,

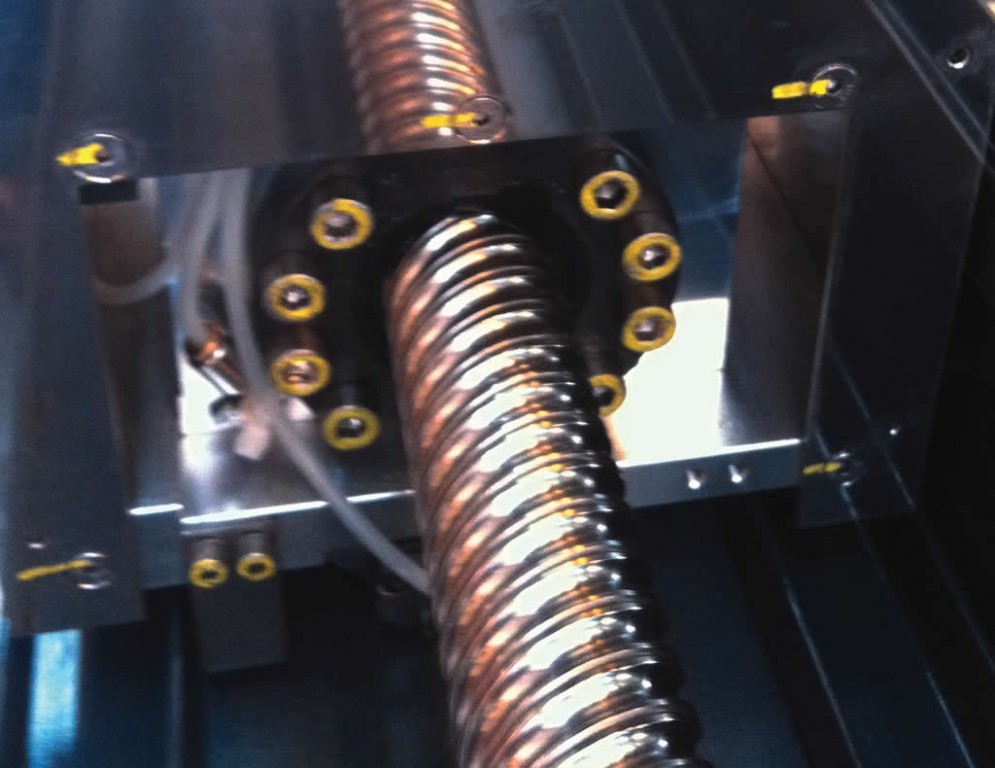

► 3-4-5 axis CNC,

► reinforced machined tubular steel bridge,

► for those who need high dimensions, precision and speed.

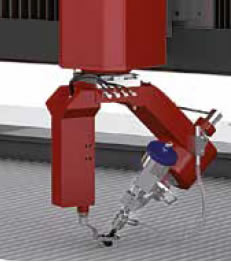

This 5 axis Evolution 3D cutting system automatically maintains by the Touch Wave™ sensor a constant distance between the nozzle and the material. This is also done while the cutting head is rotating. The interpolation of the axis can reach up to ± 69° in any 3D direction (optional ± 90° and infinite rotation).

► separate stainless steel tank,

► 3-4-5 axis CNC,

► reinforced machined tubular steel bridge,

► for those who need high dimensions, precision and speed.

This 5 axis Evolution 3D cutting system automatically maintains by the Touch Wave™ sensor a constant distance between the nozzle and the material. This is also done while the cutting head is rotating. The interpolation of the axis can reach up to ± 69° in any 3D direction (optional ± 90° and infinite rotation).

WATERJET SUPREMA - 5 AXIS 3D SYSTEM

| Net Cutting Area | X = 3.350 mm (11') Y = 1.600 mm (5') Z = 200 mm (8') A = ±69° C = ±300° |

| Inner Table Working Area | 3.600 mm x 1.850 mm (12' x 6') |

| Overall Table Dimensions | 4.800 mm x 2.300 mm x h 1.800 mm (16' x 7' 1/2 h x 6') |

| Rapid Speed | 0 - 20 mt / min (0 - 67' 7 min) |

| Weight | 5.000 Kg (11.000 lb) |

| Positioning Accuracy | ± 0,05 mm (± 0,002") |

| Repeatability | ± 0,025 mm (± 0,001") |

| Ball Bar Ø 300 mm (12”) | ± 0,05 mm (± 0,002") |

STANDARD AVAILABLE MODELS

| DX 44 | 1.250 x 1.250 mm (4' x 4') |

| DX 510 | 3.350 x 1.600 mm (11' x 5' 1/2) |

| DX 610 | 3.350 x 2.000 mm (11' x 6' 1/2) |

| DX 612 | 4.000 x 2.000 mm (13' x 6' 1/2) |

| DX 812 | 4.000 x 2.500 mm (13' x 8') |

| DX 1012 | 4.000 x 3.350 mm (13' x 11') |

| DX 620 | 6.100 x 2.000 mm (20' x 6' 1/2) |

| DX 820 | 6.100 x 2.500 mm (20' x 8') |

| DX 1020 | 6.100 x 3.350 mm (20' x 11') |

| DX 1040 | 12.200 x 3.350 mm (40' x 11') |

| DX 1340 | 12.200 x 4.000 mm (40' x 13') |

Italiano

Italiano Deutsch

Deutsch Français

Français